- New

Reference: M62SWAPADAM

Brand: ADAMAT PERFORMANCE

Custom oil sump / pan kit V8 M60/M62/S62 for swap BMW E36 E46 Z3

Reference: N54CUTCHEXTR

Brand: ADAMAT PERFORMANCE

Clutch kit up to 1040Nm, 1150Nm, 1300Nm, 1570Nm, 1700Nm of torque

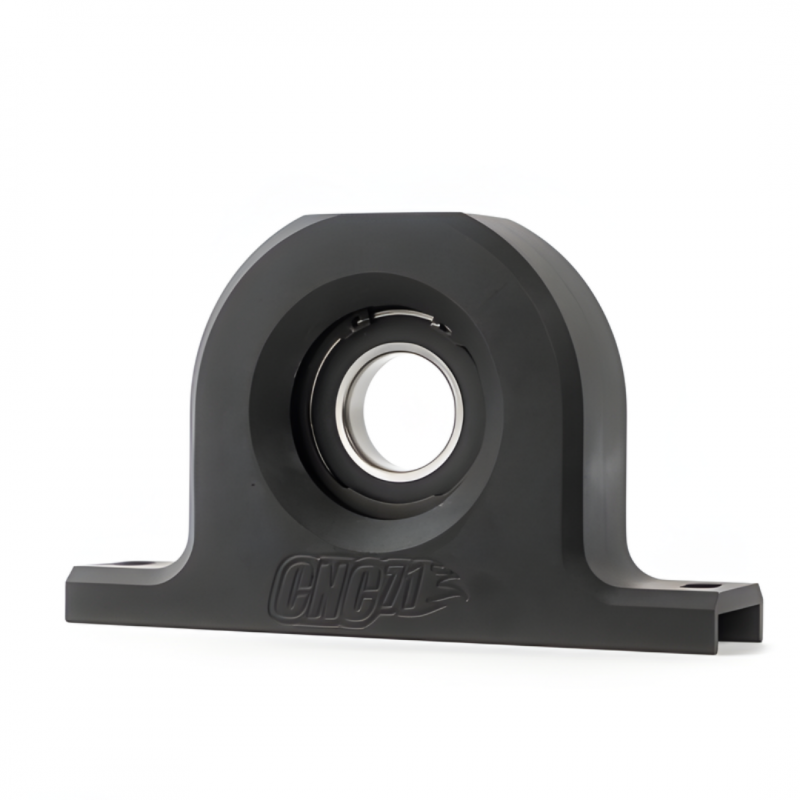

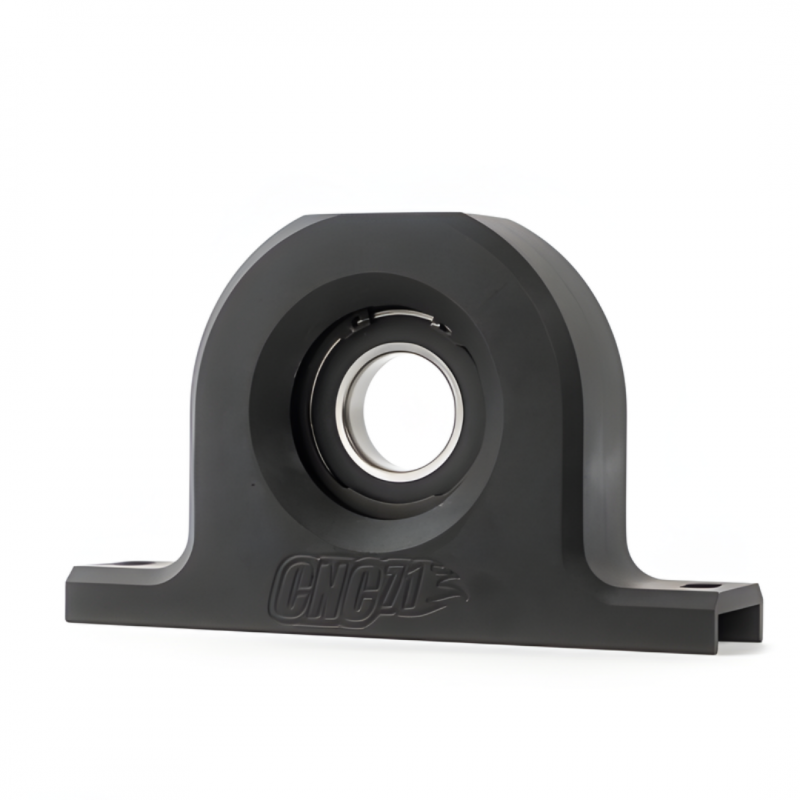

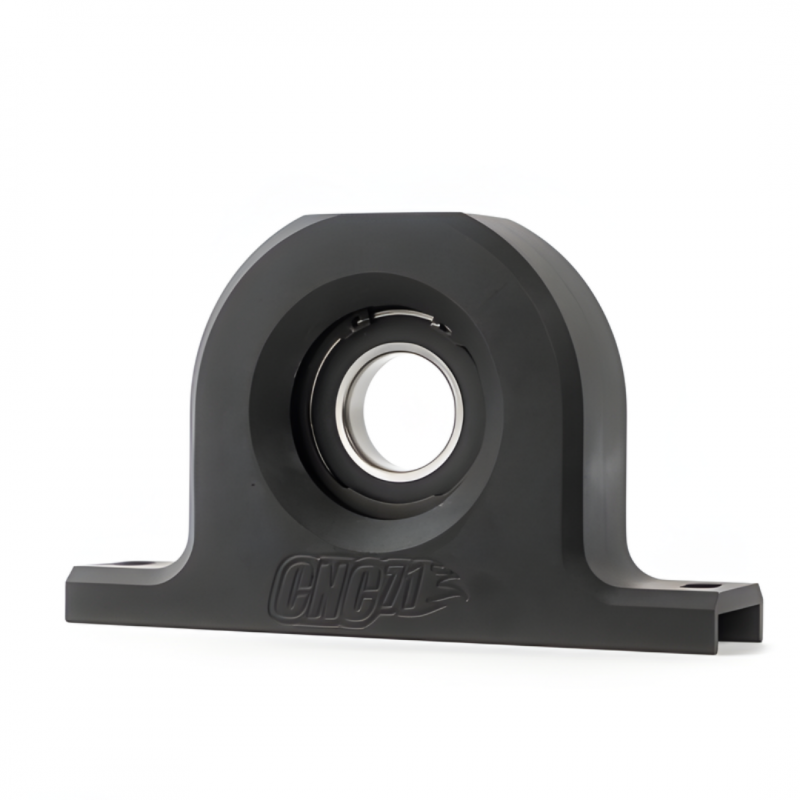

Reference: CNC71-TU-E346-WW-M

Brand: CNC71

Reference: APO-M52-C

Brand: PMC Motorsport

PMC Motorsport Oil filter lid (cap) with oil cooler fittings and 2 sensor ports BMW M52 M54 M56

Your purchase is secured by PayPal and Stripe payment system!

Fully insured delivery service by DPD or Parcelforce!

You can always return your UNUSED item for a full refund!

The standard propshaft centre support bearing bracket secures the propshaft using a rubber bush. While this provides excellent vibration and noise damping, it does not offer sufficient support under load. Combined with the effects of age, this leads to accelerated wear of the component, loss of correct propshaft alignment, and the development of play during gearchanges or throttle input.

Over time, the original bush becomes brittle, dries out, and cracks.

As the bush wears and sags, the propshaft geometry changes, increasing stress on the joints. During sudden drivetrain loading (launches, gearchanges, rapid throttle inputs), the bearing may shift off-axis, introducing slack into the drivetrain and resulting in sluggish and unpredictable throttle response.

Our rigid support eliminates this issue by keeping the propshaft firmly located in all conditions. The stiff mounting prevents the bearing from moving, ensuring correct shaft alignment and precise torque transmission at all times. The result is a more direct and predictable drivetrain response.

Notable benefits:

IMPORTANT INSTALLATION INFORMATION:

It is essential that the entire assembly is correctly aligned and operates smoothly when using this product. Please follow the steps below:

A balanced propshaft is a sensible complement to this setup. If the entire drivetrain is stiffened (for example, with aluminium bushes), it is recommended to use a new factory propshaft guibo rather than aluminium or polyurethane alternatives, in order to maximise gearbox longevity.

Reference: PSBE36-A

Brand: PMC Motorsport

PMC Motorsport BMW Gearbox Mounts Mountings E36 E39 E46 E81 E82 E87 E85 E86 E87 E89 E90 E91 E92 E93 Z3 Z4

Reference: CNC71-TU-E89-WT

Brand: CNC71

CNC71 set of aluminium bushings for the rear subframe for BMW E8x/E9x

Reference: TAWPE30-U

Brand: PMC Motorsport

PMC Motorsport Aluminium Eccentric Bushings (Mounts) for Front Lower Control Arm Rear Position for BMW E30 E36 - Uniball

Reference: ADM/GearboxMount

Brand: ADAMAT PERFORMANCE

Gearbox Bracket BMW E36 E46 Z3 RHD LHD ZF Getrag

Reference: BMW-E30-LAP-1UZ-001

Brand: Cybul Radical Solutions

The front position doesn’t require any sump modification but places the engine further forward in the car

Reference: PSE30-6C-P80

Brand: PMC Motorsport

PMC Motorsport Solid Aluminium engine mounts (mountings) / E12 (M20) / E21 (M20) / E30 (M20) (6CYL) version - 80ShA

Reference: PSE36-4C-P-R

Brand: PMC Motorsport

These lightweight aluminium alloy engine mounts with a special rubber compound insert are designed for BMW E36 / Z3 / e46 4-cylinder models. They are recommended for cars prepared for motorsport, used in Drift, Supersprint

Reference: CNC71-DP-BMW-188

Brand: CNC71

CNC71 Motorsport Driveshaft Spacers for BMW E28 E30 E32 E34 E36 TYPE 188 – 5 mm Thickness

Reference: CNC71-TU-E346-WW

Brand: CNC71

CNC71 Motorsport has the perfect solution, offering increased service intervals and a significantly improved sense of control behind the wheel

Reference: TE36-N14

Brand: PMC Motorsport

PMC Motorsport Aluminium control arm rear bushing No.14 BMW E36 E46 Uniball

Reference: CNC71-TU-E346-PAT

Brand: CNC71

Improved substitute for the original rear strut mount for BMW E36 E46 prepared by CNC71 Motorsport

Reference: PSBE36-G-B

Brand: PMC Motorsport

BMW Series E / F Gearbox Mounts Polyurethane E30 E36 E39 E46 E81 E85 E86 E87 E89 E90 E91 E92 E93 Z3 Z4

Reference: CNC71-TR-E36-WPT

Brand: CNC71

CNC71 Adjustable Front Arm Lollipops allows to ditch rubber mounts and use proper sized uniball for lollipop bushing

Reference: PSE36M-G70

Brand: PMC Motorsport

PMC Motorsport Aluminium engine mounts mountings BMW E36 E46 E85 E86 E90 E91 E92 E93 Z3 Z4 M M3 Versions - Polyurethane 70ShA

Reference: PS350-P-B

Brand: PMC Motorsport

PMC Motorsport Aluminium engine mounts mountings Nissan Z33 350Z Fairlady Z - Polyurethane 70ShA

Reference: TBTE36-A

Brand: PMC Motorsport

PMC Motorsport Solid aluminium subframe bushes BMW E36

Your review appreciation cannot be sent

Report comment

Report sent

Your report cannot be sent

Write your review

Review sent

Your review cannot be sent